INDUSTRIAL REPAIRS, SIMPLIFIED

Experienced Technicians

Reliable Service

Cost-Effective Solutions

Comprehensive Repair Solutions for Your Business

At ProCore Industrial, we specialize in providing top-notch repair services for a wide range of industrial equipment. Our team of skilled technicians is dedicated to delivering efficient and effective solutions to get your operations up and running in no time.

SERVICES

Servo Motor Repair

High-precision actuators that control position, speed, and torque in CNC machines, robotics, and automation systems.

Why Repair Matters:

-

Restores accuracy

-

Prevents unplanned downtime

-

Extends overall service life

Key Benefits:

-

Rapid fault diagnosis

-

Bearing, encoder, and brake refurbishment

-

Vibration analysis and dynamic balancing

-

Full-load performance testing

Typical Failures:

-

Wear

-

Contamination

-

Misalignment

-

Electrical faults

-

Overheating

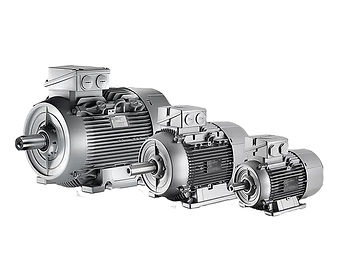

AC & DC Motor Repair

We repair all spindle, servo, AC, and DC motors of any horsepower or rewind style.

Process:

1.

2.

3.

Coil measurement and documentation

Controlled burnout in a pollution-controlled furnace

Core media-blasting and degreasing

4.

5.

VFD-rated rewinding, insulation, and curing

AWA analyzer verification

Hydraulic & Pneumatic Repair

Procedure:

-

Complete teardown

-

Ultrasonic cleaning

-

Electronics bench testing

-

Piston scoring removal

-

Contaminant flush

-

Precision re-bore

-

Surface resurfacing

-

Installation of premium seals and bearings

Industrial Electronics Repair

Equipment Covered:

-

Drives (AC/DC)

-

Programmable Logic Controllers (PLCs)

-

Printed Circuit Boards (PCBs)

-

I/O modules

-

Sensors

-

Controllers

-

Safety systems

Workflow:

-

Disassembly of equipment

-

Component-level diagnostics

-

Board-level rework

-

Calibration

-

Final system verification and testing